Inkjet/Toner Hybrid PCB Printing

After a fair amount of trial and error I’ve got a reasonable method for printing a PCB with a silkscreen using a modified inkjet printer. This isn’t a new idea but I haven’t really seen the inkjet/toner hybrid method detailed so I thought I’d share my experience and tips. The great thing about the hybrid method is that it stands up to Cupric Chloride etchant which is helpful when you don’t have access to Ferric Chloride.

The videos are a bit long but I wanted to share some of the detail, I hope it’s helpful.

This method comes with 2 warnings (The later you should take seriously)

- Acid is dangerous

- Epson inkjet printers are dangerous (for your sanity)

Part 1

Part 2

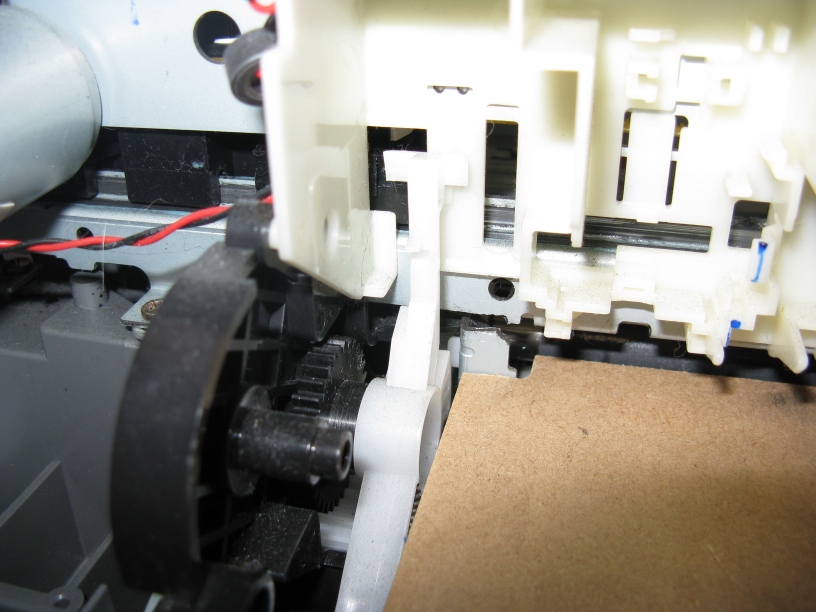

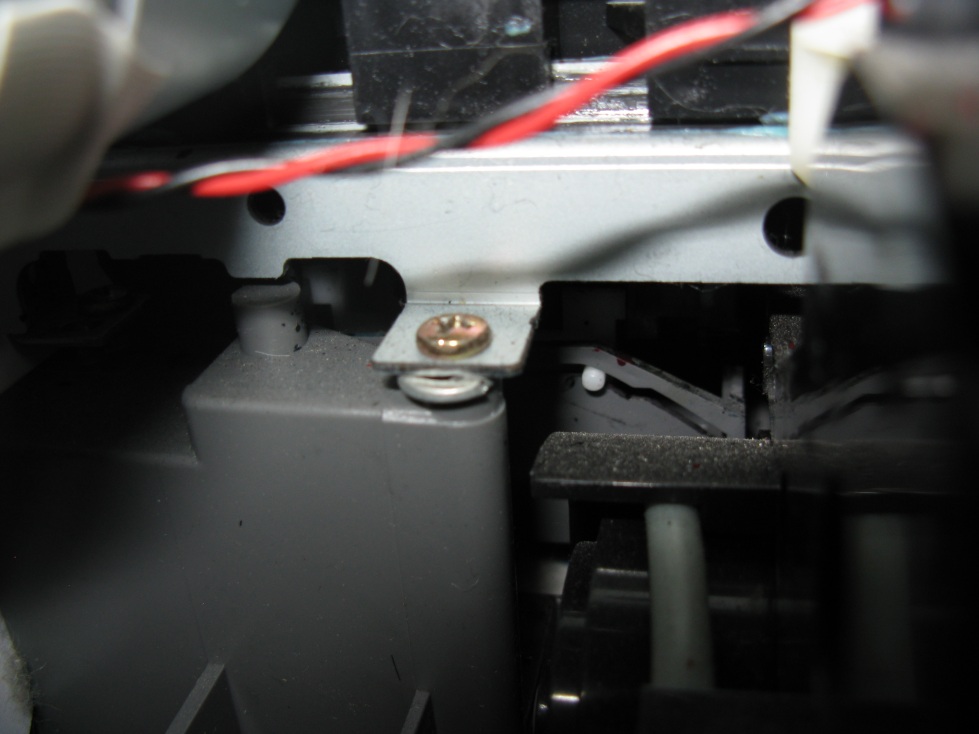

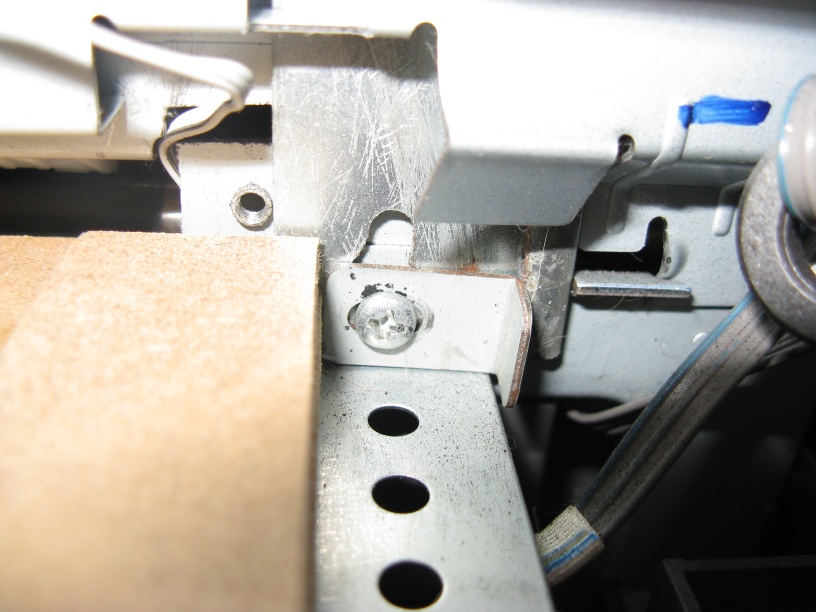

Here are some shots of the printer modifications viewed from the rear of the printer. It’s a bit of a pain to get a hacksaw blade in and cut the carriage but fortunately you only have to cut it in 2 places.

Left side cut

Left side spacer washer

Right side cut and spacer bracket.

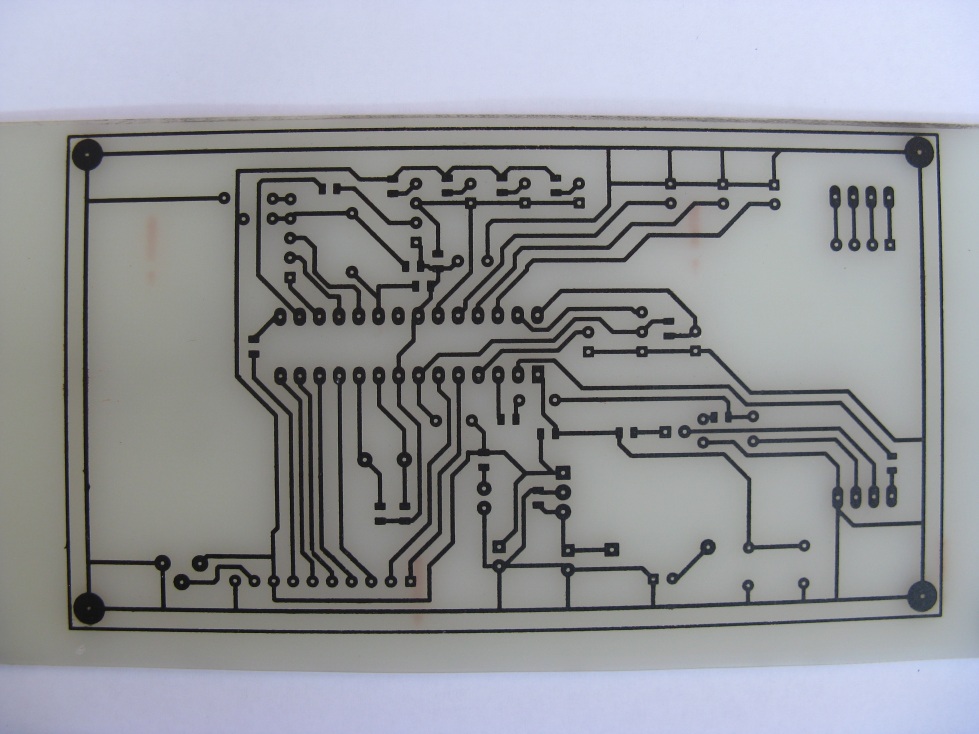

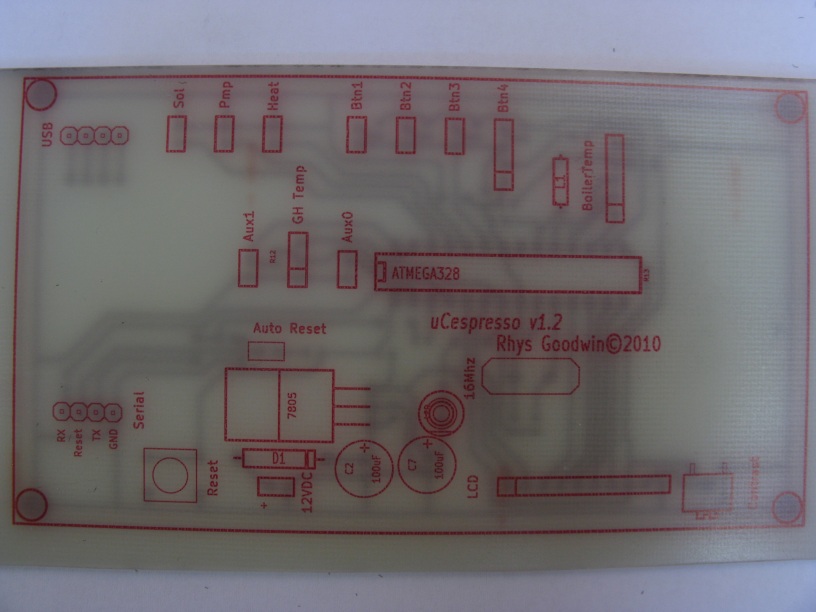

And here’s a shot of the board just after etching..

Hopefully in the next few weeks you’ll be able to see the project for which this board is intended. No prizes for guessing what it’s going to be!

Links

Etching with Air Regenerated Acid Cupric Chloride -This is the etchant used in the video

Hacking A Printer To Directly Print PCB’s (CNCZone Forum) – I got most of my information from here before I got started