1 Year Workshop Renovation

…And I’m back. Yep, it’s been a while since I shared anything much here. That’s partly because I’ve been spending so much of my free time converting my decrepit old garage into a tidy workshop, a project that I started just over a year ago.

It’s been one of those of projects that starts out as a small seed of an idea, something that will take just a few weeks but then grows one “If I’m going to this I might as well do that” statement at a time until it carries on for an entire year. In project terms it’s clear that I failed to define the requirements and scope up front!

In case you don’t make through to the end this very long set of photos I’d like to say a big thanks at the beginning of the post to:

- My wonderful wife who has not only put up with me spending so much time on this project over the last year has also done ALL the painting that you’ll see below

- My good friend Rick who helped me through all the electrical work and made sure that I didn’t burn the workshop, the house or myself to the ground

- My good friend Simon who helped with external weather proofing.

- The guys up at Hill Lumber in East Tamaki for their advice and patience for a total newbie who couldn’t even tie down a trailer on my first of many visits. If you’re looking for great timber and building materials at the best prices around check them out.

The old garage which is 3.6m x 7.2m was built at the same time as the house in 1956. It has a side entrance and main entrance, which opens out into the carport, which opens out onto the driveway. Having the carport for the car meant that I could convert the old garage into a workshop for anything from woodwork to metalwork, plastics, electronics etc.

Inside, looking out through the carport. Before starting the project.

Inside, looking out through the carport. Before starting the project.

My initial intention was just to replace the rotten framing and line the interior with ply. Water had been running under the door when it rained heavily and would flow to one side. Consequently, the bottom plate and the first ~150mm of the most of the studs down one side had pretty bad rot. Water had been coming in the top and around the sides of the window on the back wall resulting in yet more rot. The right-hand side (which has the side door on it) was pretty solid.

The first step was to clear out the bottom plate. I used a couple of the redwood planks for the old workbench to prop up the wall under the top plate. Most of the bottom plate cleared out easily because it was so rotten. I used the angle grinder to cut off the old steel anchor pins.

Old bottom plate all cleared out

Old bottom plate all cleared out

The next step was to put in the new bottom plate using dynabolts and with a strip of damp-proof course to prevent moisture in the concrete slab from being absorbed into the wood.

With the new bottom plate it was time to sister the rotten studs with new ones.

This all went well and I worked my way along the left hand wall until I reached the first window, at which point I stood back and admired my handy work and for my first ‘building’ project I was pretty happy. It all looked solid and reasonably straight and I thought since I’d come this far I really should replace the old rusty louvre window. I picked up a second hand aluminum window off TradeMe.

Next I moved on to the back wall and back window. This time I had to:

- Take care of the partially rotten top plate by re-enforcing with a sub-top plate

- Install new studs and remove the old window and rotten diagonal framing

- Install a new window frame and window – again I managed to find a second hand aluminum window that was about the right size.

I came across this excellent site which describes how to correctly frame a rough opening for a window.

At this stage I had dealt with all the rotten framing and had a generally sound building. I figured since I’d come this far I should really doing something about the very pitted rough stained floor. In the end I settled on getting a guy in to grind, patch and lay two coats of epxoy. Oh and while I’m at it I might as well install a secondhand roller door.

I was averagely happy with the floor. There are a lot of grind marks and there were a few other issues but I won’t go into that. It’s about 1000% percent better than it was. Finally it was time to start lining. Or was it? As I surveyed the project so far I figured it only made sense to line the ceiling as well as the walls, and if I was going to line the ceiling it would be a shame to miss the opportunity to install insulation.

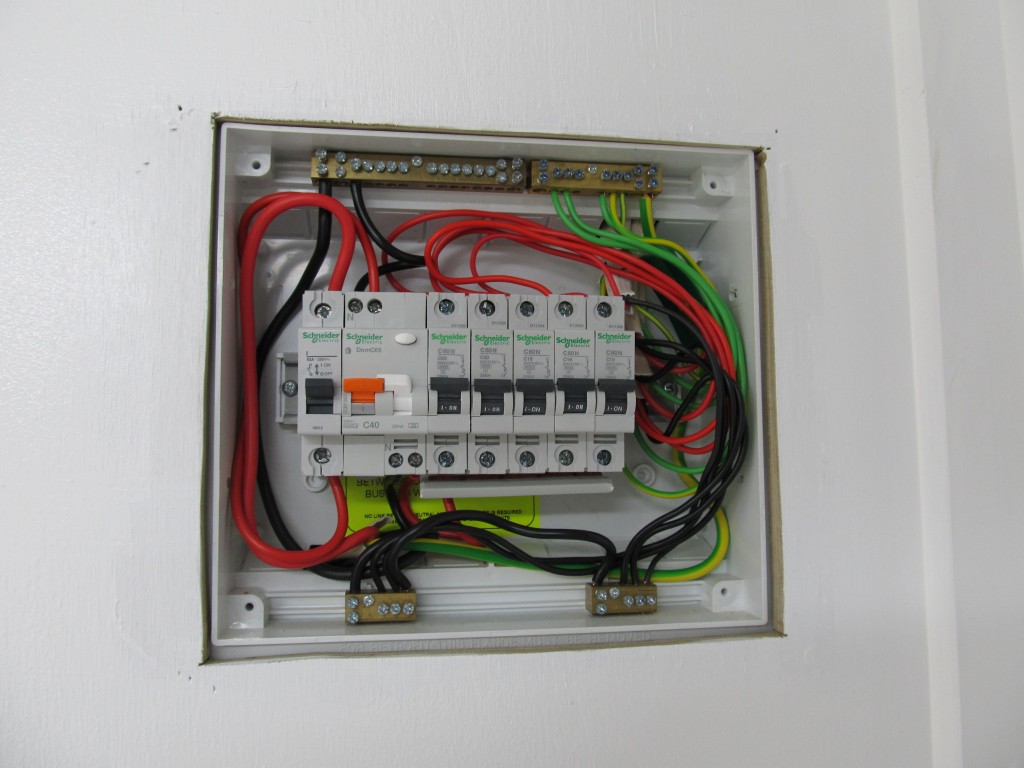

Of course before I could start any of the lining I had to consider wiring – power points, lighting etc. With a whole new set of electricals I should really install a new main cable back to the house to replace the 50+ year-old one that was there. That task lead me to cut a trench across the path between the workshop and the house. And let’s face it, while you’ve got a trench open you’d be silly not to lay network cables back to the patch panel in the house along with a pipe for water supply. Right?

Did I go overboard on the Ethernet?

Did I go overboard on the Ethernet?

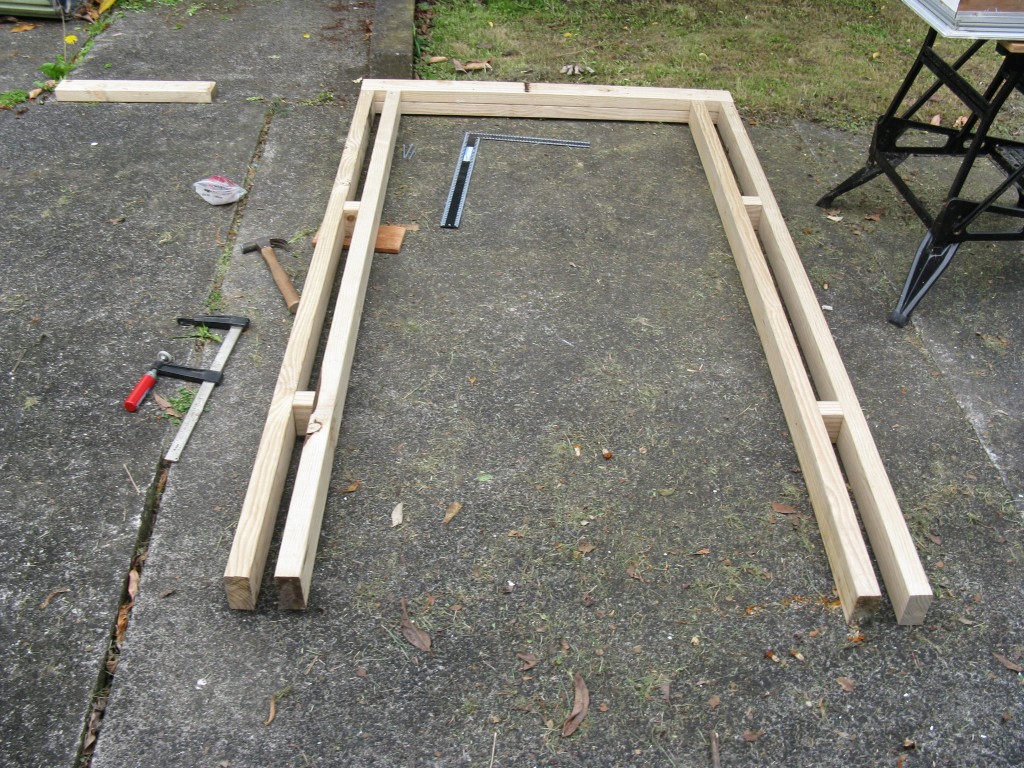

I had to add additional framing to support the ceiling panels

I had to add additional framing to support the ceiling panels

696 Watts of fluorescent lighting. Switched in 3 sets of 2.

696 Watts of fluorescent lighting. Switched in 3 sets of 2.

And finally on to the wall lining and switchboard.

All that’s really left is the workbench and I’ll put that up in another post (hopefully) soon!