Workshop and Workbench Update

Back in January I posted about my workshop renovation. Since then I’ve completed the network outlets, wired up the security alarm and built a workbench.

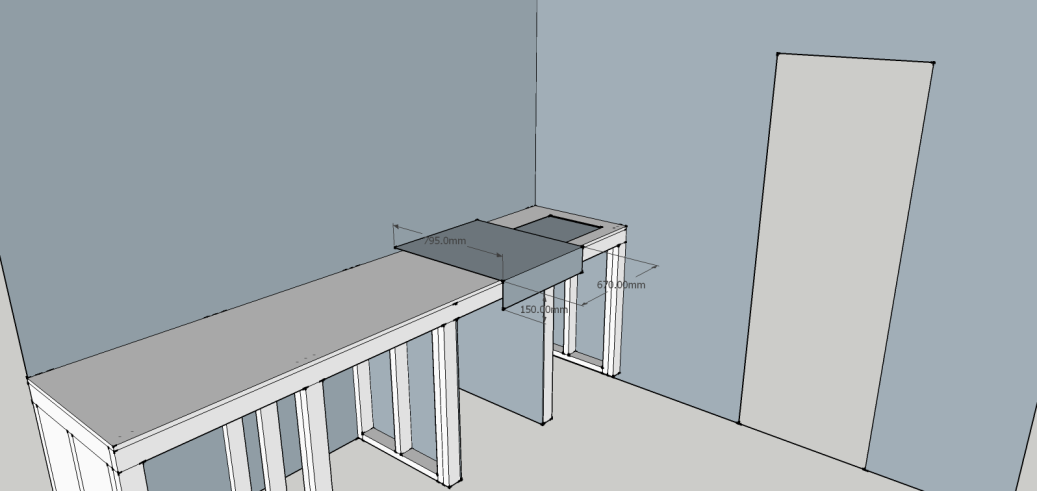

Initial workbench concept done in Sketchup.

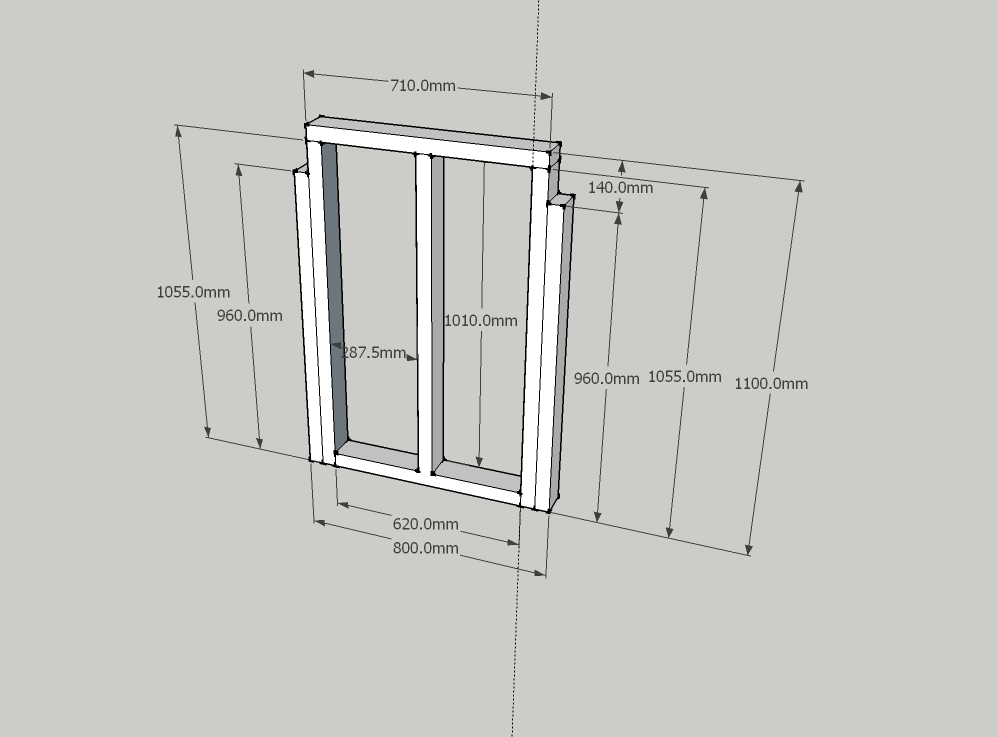

Each leg is a 2×4 and ply torsion box. Well I had to do something with all the ply offcuts from lining the walls!

The ply is screwed and glued to the 2×4 box. These Irwin QuickGrip clamps

Yes the bench is built like the proverbial brick house. Several people have made reference to an earthquake or bomb shelter.

I installed a tub with removable insert to save bench space. (Good call Niten!) Not sure when I’ll to get this plumbed in.

3mm steel galv plate for the metalworking area.

I wanted the plate to sit flush with the surface of the bench so I routed out 3mm across the surface where the plate goes. 25mm per pass. Sucker for punishment? Perhaps. Actually the top was ok – the front – don’t ask. This was done with a Makita RP1800 Router

I then glued the steel plate in with Contact Adhesive

This is an original ‘Made in England’ Record vice which I did a quick restoration job on. Very robust.

These record vices are now sold under the Irwin brand.

My favourite part…What would a workshop be without a server……tool drawer.

I’d like to add a few more but who knows when I’ll get around to it. I used a Bosch Multi tool to cut out the little recesses where the rails are mounted. Can highly recommend these.

And yes you can cut through a CD ROM drive with a Jig Saw

It’s already getting messy!